A Cost Effective Method of Increasing Railroad Rail Non-Destructive Testing Speed and Reliability

Background:

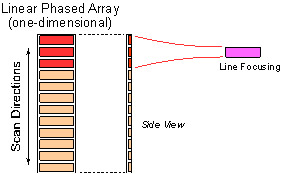

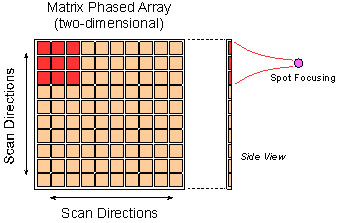

The Federal Railroad Administration (FRA) has funded research into the utilization of advanced ultrasonic inspection technology of rail in the past (DOT/FRA/ORD-06/17 July 2006, RR08-25 August 2008) with varying results. Currently FRA approved inspection systems are slow, not more than 25 mph, and use up to nine discrete single element ultrasonic transducers that are arranged in such a way that each transducer covers area of interest in the rail head by arranging the position and launch angle (http://www.sperryrail.com/ultrasonics.html). These nine transducers can be replaced by one single Matrix Phased Array probe. Unlike an ordinary linear phased array probe, electronic grouping of the elements can be done in two dimensions as shown in the figure below. By grouping certain number of elements together, it is not only possible to focus the beam into a small spot with steering capability but also possible to change the focal length and depth as well. One of the biggest advantages of using phased array probe is the ability of electronic scanning with a predictable beam manipulation. MPA probes can make the electronic scanning more efficient in both longitudinal and transverse directions at a much faster inspection speed.

(a) Linear phased array probe

(b) Matrix phased array

Figure: Phased array ultrasonic probe: (a) linear phased array and (b) matrix phased array.

Scope of Work:

- Modeling and simulation: Matrix phased array probes will be modeled and simulated for their beam focusing and steering to fit for the rail inspection in terms of geometries, locations and flaw orientations.

- Design and fabrication of prototype probes: Based on the modeling and simulation results, at least two versions of MPA probes will be designed and fabricated.

- Testing on rails: MPA probes will be tested on specimens with controlled flaws to validate the modeling and simulation results.

- Develop a prototype inspection system: With the lab test proven MPA probes, a prototype inspection system will be designed and integrated.

- Transition the technology to inspection system manufacturing company.

Goals of work:

• Reduce the number of transducers used for the inspection from six to one MPA probe

• Increase inspection coverage of the rail web.

• Increase the ability to detect defects when inspecting from the head of the rail.

• Increase the ability to detect and measuring transverse defects (TD).

• Allow real-time inspection of rail with different head wear profiles.

• Remove the inspection process as the limiting factor for inspection speed.